Universal Clamps are one of the most versatile and essential tools used in industrial settings today. They provide a secure and reliable method to hold objects in place during various processes. From construction sites to manufacturing plants, Universal Clamps play a significant role in improving efficiency, safety, and precision. In this article, we will explore the innovative applications of Universal Clamps in industrial environments and why they are becoming a crucial tool for modern industries.

Understanding Universal Clamps

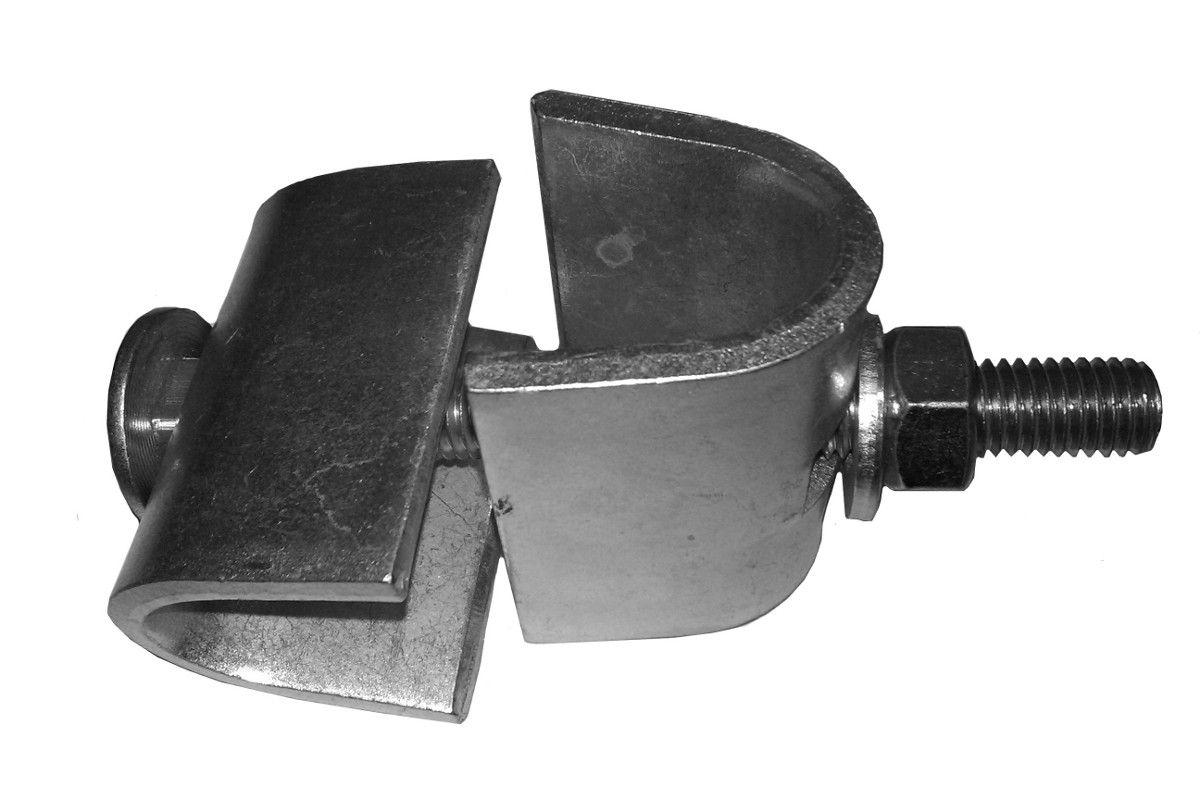

Universal Clamps are designed to hold different shapes and sizes of objects firmly in place. Unlike traditional clamps, they are adjustable and flexible, making them suitable for a wide range of tasks. They are made from durable materials such as steel, aluminum, or reinforced composites, which ensures long-lasting performance even under heavy loads.

The primary function of Universal Clamps is to stabilize objects during operations such as welding, cutting, assembly, and machining. Their adaptability makes them suitable for irregular or hard-to-hold shapes, which traditional clamps often cannot handle.

Applications in Welding and Fabrication

One of the most common uses of Universal Clamps is in welding and fabrication. Industrial workshops often require precise positioning of metal sheets, pipes, and structural components before welding. Universal Clamps hold these objects securely, allowing welders to work safely and accurately.

By using Universal Clamps, workers can ensure that parts do not shift during welding, reducing the risk of errors and improving the overall quality of the finished product. They also allow for quick adjustments, making it easier to handle complex or large projects without constantly repositioning the material.

Enhancing Efficiency in Assembly Lines

In assembly lines, time is crucial, and efficiency is key. Universal Clamps help in holding components together while machines or workers complete assembly tasks. For example, in electronics or automotive assembly, clamps can hold small parts in place, ensuring precise alignment and reducing mistakes.

Universal Clamps reduce the need for additional fixtures, which saves both time and space on the assembly floor. Their ability to quickly adjust to different sizes and shapes makes them ideal for industries that handle a variety of products on the same line.

Supporting Machining and Metalworking

Machining processes such as drilling, milling, and cutting require objects to remain stationary. Universal Clamps provide a reliable solution for holding workpieces on machines, ensuring accuracy and safety.

For metalworking shops, these clamps can handle irregularly shaped materials that traditional vices cannot secure. This flexibility allows machinists to take on more complex tasks while maintaining consistent results. Universal Clamps also reduce the risk of material movement, which can prevent damage to expensive equipment or finished products.

Applications in Construction Projects

Construction projects often involve large and heavy materials that need to be held in place during assembly or installation. Universal Clamps are used to secure beams, panels, and piping systems temporarily. This ensures that workers can complete installations safely without relying solely on manual support or temporary scaffolding.

In addition, Universal Clamps can be used for formwork in concrete construction. They hold wooden or metal forms firmly together, providing stability until the concrete sets. This use of clamps reduces the risk of misalignment and ensures a smooth, level surface in the finished structure.

Innovative Uses in Industrial Robotics

With the rise of industrial automation, Universal Clamps are finding new applications in robotics. Robotic arms often need to pick up, hold, or manipulate objects of varying sizes and shapes. By integrating Universal Clamps into robotic systems, manufacturers can improve precision and reduce the need for custom fixtures.

This approach is particularly valuable in industries such as automotive manufacturing, electronics, and packaging, where products may vary frequently. Universal Clamps provide a cost-effective and adaptable solution for automated systems, increasing productivity and reducing downtime.

Enhancing Safety in Industrial Operations

Safety is always a priority in industrial settings. Universal Clamps help reduce accidents by securely holding materials that might otherwise shift, fall, or tip over during operations. Workers can focus on their tasks without worrying about instability or injury caused by moving objects.

For example, in welding, machining, or assembly tasks, clamps prevent hands or tools from slipping. In construction, they reduce the chance of heavy materials falling during installation. By improving stability and control, Universal Clamps contribute to a safer workplace for all employees.

Reducing Costs and Increasing Flexibility

Investing in Universal Clamps can also save costs for industrial businesses. Because they are adjustable and versatile, a single set of Universal Clamps can replace multiple specific clamps or fixtures. This reduces the need for extensive inventories of specialized equipment.

Moreover, their durability ensures that they can withstand repeated use over many years, minimizing replacement costs. Their flexibility allows industries to handle different projects without buying new tools for each task, making Universal Clamps a cost-effective solution for long-term operations.

Future Trends in Universal Clamps

The future of Universal Clamps in industrial settings looks promising. Manufacturers are developing clamps with improved ergonomics, stronger materials, and smarter designs to handle even more challenging tasks. Innovations such as quick-release mechanisms, adjustable angles, and lightweight materials make Universal Clamps easier to use and more effective.

As automation and robotics become more widespread, Universal Clamps are expected to play an even larger role in industrial efficiency. Their adaptability makes them suitable for a variety of emerging technologies, ensuring that they remain a valuable tool in modern manufacturing and construction.

Conclusion

Universal Clamps are no longer just a simple tool in industrial settings. Their versatility, strength, and adaptability make them essential for modern construction, manufacturing, and automation. From welding and machining to assembly and robotics, Universal Clamps improve efficiency, accuracy, and safety across a wide range of applications.